Retrofit Parts

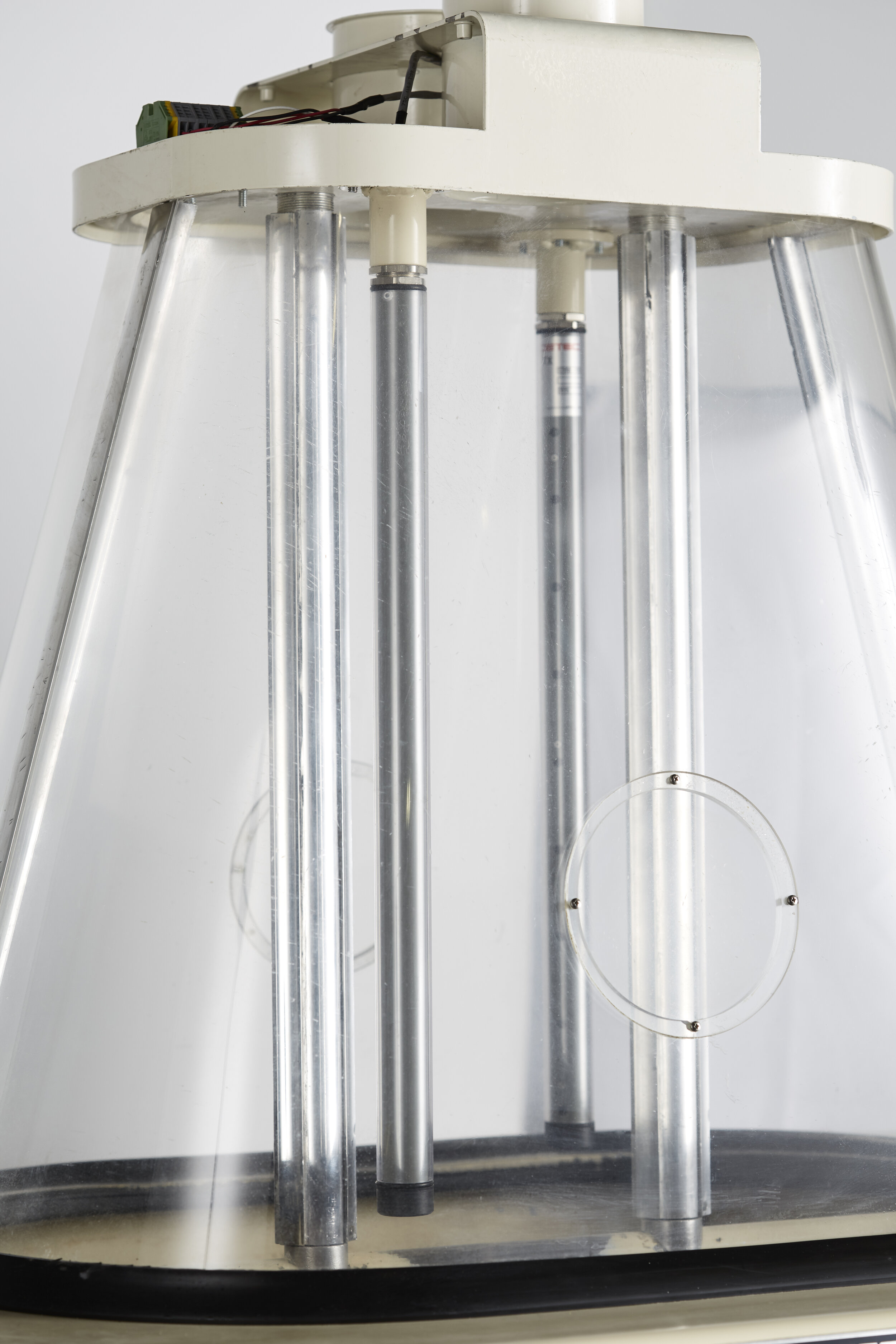

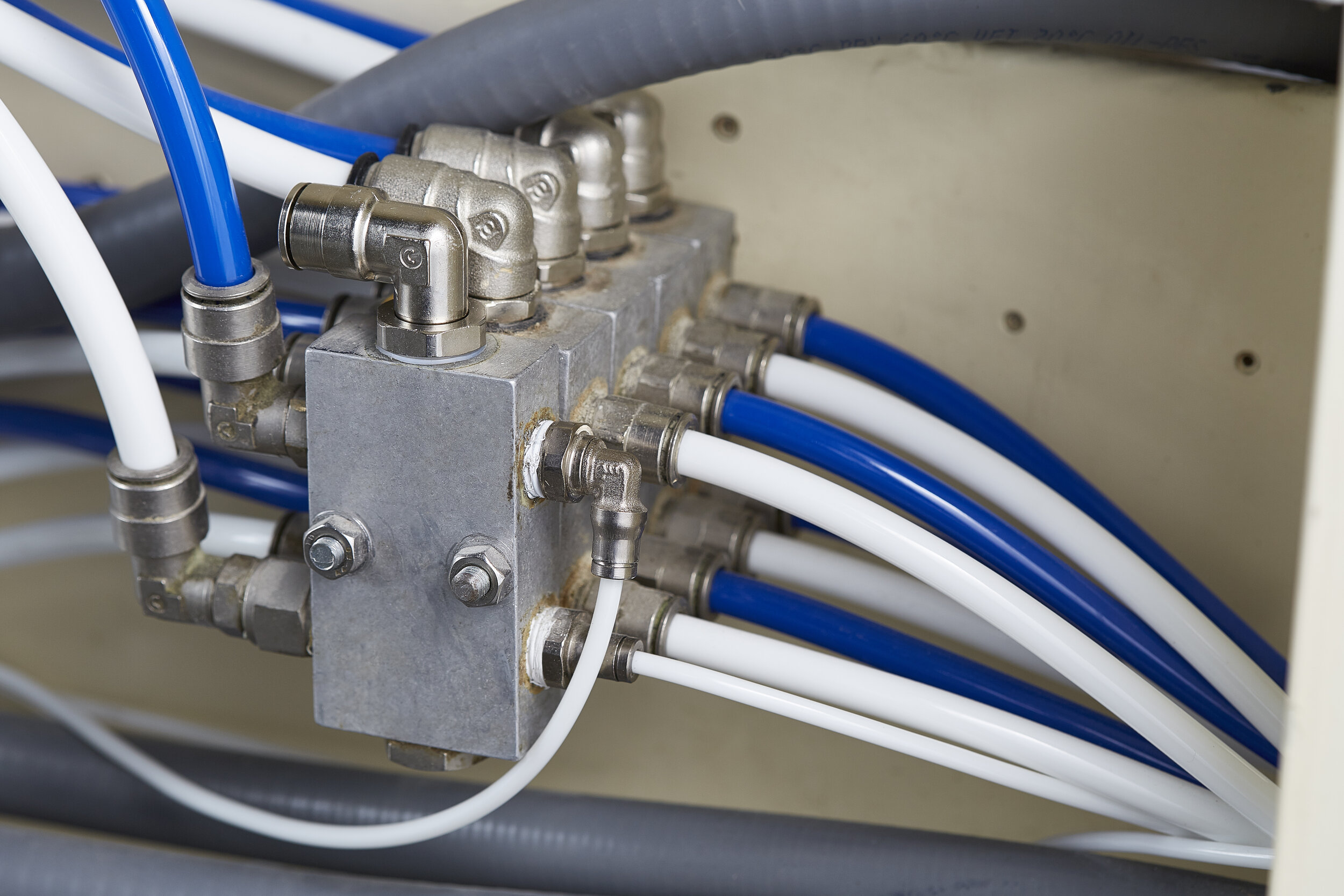

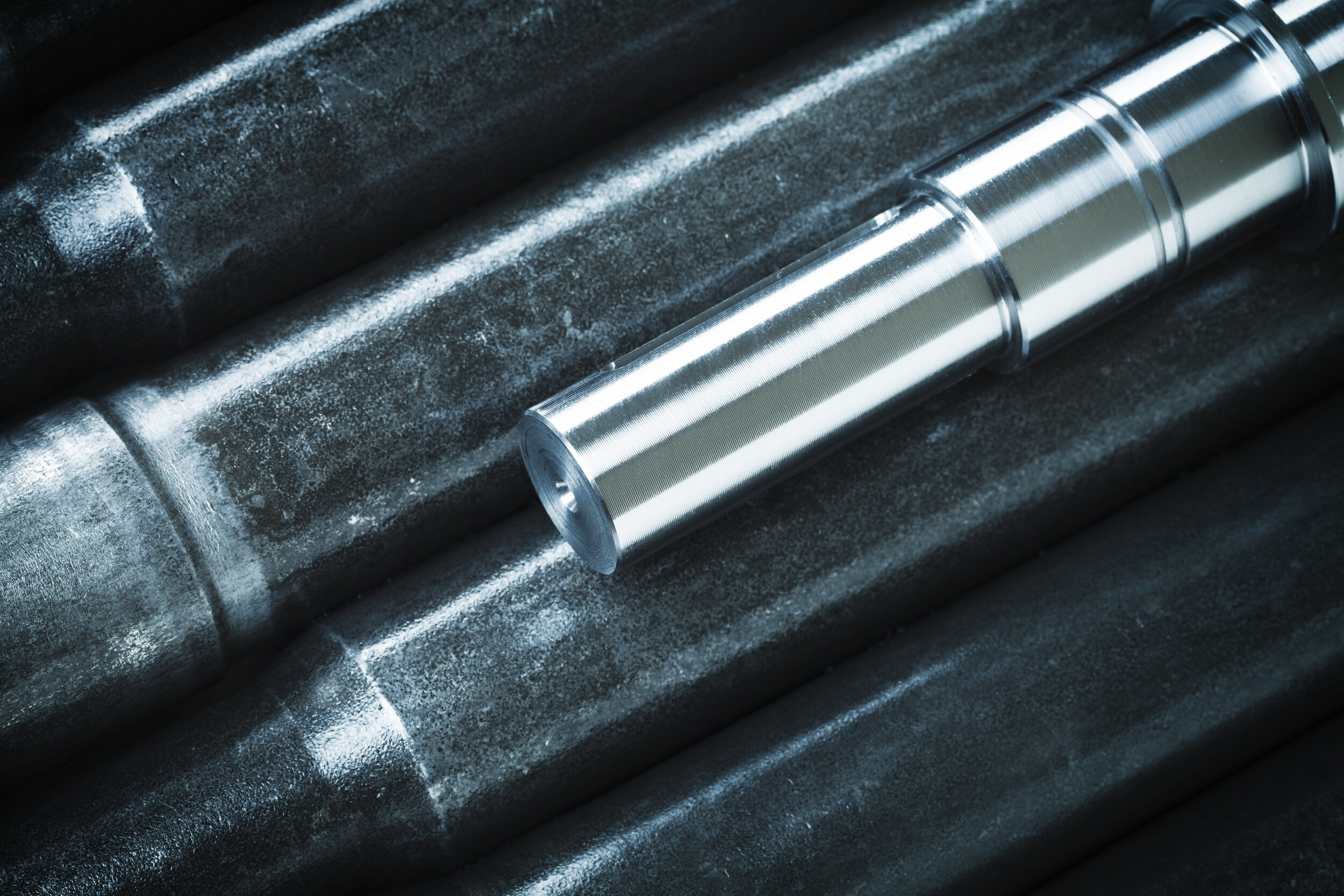

We specialize in improving component efficiency, large or small. With new and improve materials and with continuous technology improvements, we have the right tools and machinery to remake any retrofit parts to extend the lifespan of your equipment. We are constantly seeking out new-innovative ways to bring old equipment back to life. It’s our goal to meet the requirements made to improve your equipment’s productivity and quality of product. Take our roller mill infrared level probes for example; Entirely retrofitted to your existing roller mill’s top-hopper (single or divided), this single improvement can change the lifecycle and overall yield of your stand.